|

|

|

Extending the process limits of laser polymer

welding with high-brilliance beam sources

|

|

|

|  |

|

|

|

|

|

|

|

|

|

|

|

|  |

|

|  |

|

|  |

|

|  |

|

|  |

|

|  |

|

|  |

|  |

| The Polybright research project has received funding from the European Community´s 7th Framework Programme (FP7/2007-2013) under grant agreement n° NMP2-LA-2009-228725 |

|  |

|  |  |

|  |

|  |

| News |

|  |

|

|  |

|

|  |

|  |

|  |

|  |

|

| Welcome

|

|

The laser welding of polymers became over the last decade a strong competitor for the conventional joining technologies and significantly raised the industrial interest for this technique. Main factors contributing to the successful evolution of the laser welding of polymers lay within the process related benefits such as: contactless processing, high flexibility in time and product, high automation degree and precisely controlled and localized energy input.

POLYBRIGHT Time Chronicle (PDF)

|

|

|

|

Concept and objectives

|

|

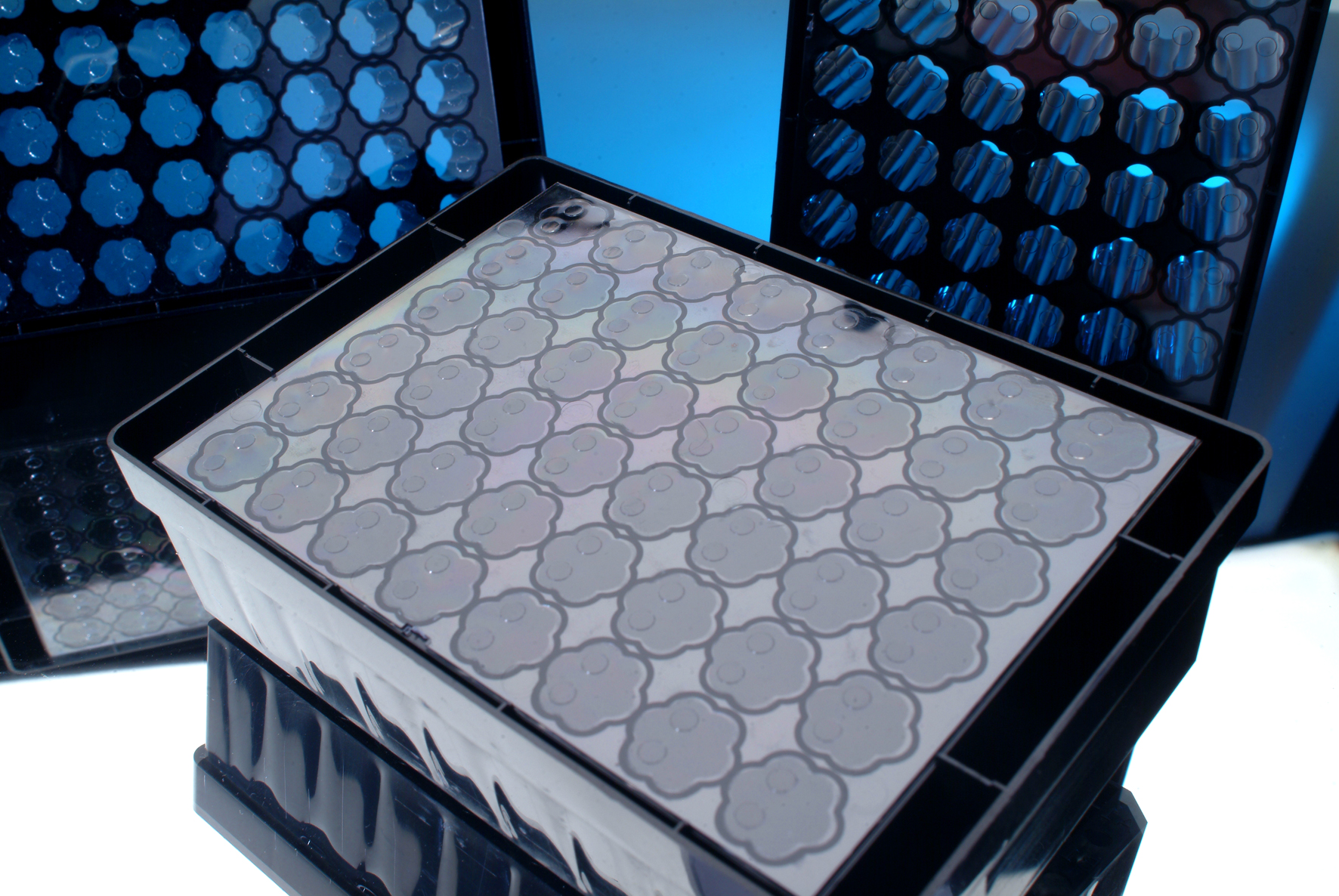

Plastics play an important role in almost every facet of our lives in a wide variety of markets, from everyday products such as food and beverage packaging, furniture and building materials to high tech products in the automotive, electronics, aerospace, medical and other areas. Since the monolithic construction is in most of the cases impossible, the joining technology plays a central role for the complete manufacturing of polymeric products. Starting with the development of the high power diode lasers in the mid 90's the laser welding of polymers enjoyed o continuous increase of its application fields and became an established process. Nowadays, based on the development of novel laser sources new opportunities arise for this versatile joining technology.

Therefore, the main objective of the EU-funded POLYBRIGHT research project is to break new paths for laser beam welding of advanced polymeric materials. To benefit from current developments in the field of high brilliance laser sources, main focus is the application of diode lasers and fibre lasers in the Near-Infrared (NIR) spectral range as well as beam shaping and scanning techniques. The projects aims for challenging the limits of conventional polymer joining processes as well as related existing production systems and equipment. A significant improvement of the process performance and the development of innovative system technology concepts in order to reduce the investment cost for laser polymer welding systems are expected as project outputs.

In this way POLYBRIGHT will contribute to guarantee Europe's leadership in the field of laser applications and through the foreseen dissemination activities will accelerate the know-how transfer towards the industrial field. On the economical and social level the POLYBRIGHT Project aims to enhance the business opportunities related to the entire value chain in the laser welding of polymeric products.

|

|

|

|

|

|

|

|

last update 2014-01-10 |

|

© POLYBRIGHT 2009 |

|

|

|